AQ-F213A FEEDER PROTECTION IED

The AQ-F213A feeder protection device provides optimal performance for medium-voltage (main) or high-voltage (back-up) protection, control and monitoring applications. AQ-F213A integrates protection, control, monitoring, measuring, communication and extensive diagnostics information in one compact package. The device has a fully modular hardware construction with three (3) empty I/O slots. This gives the device a high level of flexibility. You can simply plug in additional I/O or communication cards according to application needs.

The development of the AQ-F213A feeder protection device uses the latest available technologies, which provides protection engineers with more options and a completely new dimension to protection. The device has many features which guarantee its maximum usability. These include the highly customizable graphic interface, the ability to store PDF files and other supportive documents, and extensive user log information. Additionally, the powerful configuration and setting software tools are easy to configure and free of charge.

We offer five (5) variants of the AQ-F213x feeder protection device, A-E. AQ-F213A includes basic feeder protections with an excellent price–performance ratio.

Highlights:

- Low-impedance restricted earth fault protection.

- Harmonics protection and control.

- A 5-shot scheme-controlled auto-recloser.

- Download PDF

- AQ 200 Series flyer v2.01 (English)

- AQ 200 Series product catalogue v1.03 (English)

- AQ-F213 Product flyer v1.02 (English)

- AQtivate PRO Flyer v1.00 (English)

- AQ-F213 Instruction manual v2.04 (English)

- AQ 200 series DNP3 device profile v4.00 (English)

- AQ 200 series DWG connection drawings (.zip file)

- AQ 200 series IEC 103 interoperability list v1.00 (English)

- AQtivate 200 Instruction manual v2.02 (English)

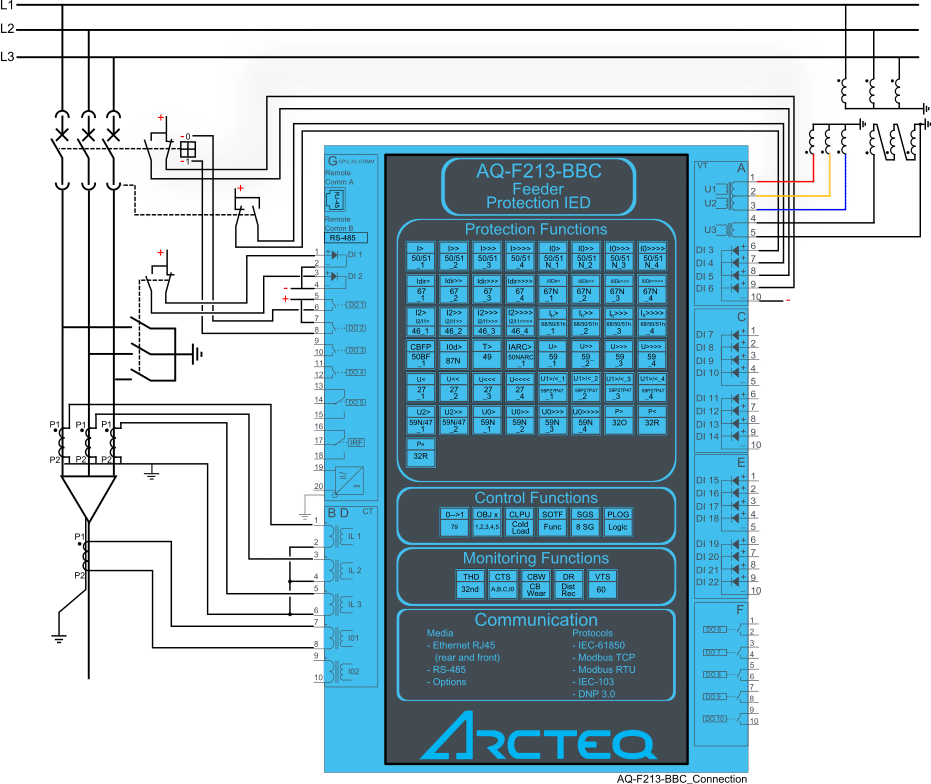

- Non-directional overcurrent (I>; 50/51) - 4 stages (INST, DT or IDMT)

- Non-directional earth fault (I0>; 50N/51N) - 4 stages (INST, DT or IDMT)

- Negative sequence overcurrent/ Phase current reversal/ Current unbalance (I2>; 46/46R/46L) - 4 stages (INST, DT or IDMT)

- Harmonic overcurrent (Ih>; 50H/51H/68H) - 4 stages (INST, DT or IDMT)

- Circuit breaker failure protection (CBFP; 50BF/52BF)

- High-impedance or low-impedance restricted earth fault/ Cable end differential (I0d>; 87N)

- Resistance temperature detectors (RTD)

- Line thermal overload (TF>; 49F)

- Arc protection (IArc>/I0Arc>; 50Arc/50NArc) (optional

- Number of objects to control and monitor: 5

- Number of indicators to monitor: 5

- Number of setting groups: 8

- Cold load pick-up

- Switch-on-to-fault

- Auto-recloser (0 → 1; 79)

- Phase, sequence and residual currents (IL1, IL2, IL3, I01, I02)

- Current transformer supervision

- Circuit breaker wear monitoring

- Measurement recorder

- Measurement value recorder

- Event recorder (max. 15 000 permanent event records)

- Disturbance recorder (max. 100 records á 5 seconds at 3.2 kHz sampling)

COMMUNICATION INPUTS

- RJ-45 100 Mbps Ethernet (front panel, fixed)

- RJ-45 100 Mbps Ethernet and RS-485 (rear panel, fixed)

- 2 x RJ-45 100 Mbps Ethernet with an IRIG-B input (optional)

- 2 x ST 100 Mbps Ethernet with an IRIG-B input (optional)

- 2 x LC 100 Mbps Ethernet (PRP/HSR) (optional)

- RS-232 serial fiber (PP/PG/GP/GG) (optional)

COMMUNICATION PROTOCOLS

- IEC 60870-5-101/104

- IEC 60870-5-103

- Modbus/RTU and Modbus/TCP

- DNP3

- SPA

- Current inputs: 5

- Voltage inputs: 3

- Digital inputs (fixed): 6

- Digital outputs (fixed): 5

- Number of empty slots: 3

- Digital inputs: +8/16/24 (optional)

- Digital outputs: +5/10 (optional)

- Milliampere I/O module (4 mA outputs + 1 mA input)

- Arc protection module (4 sensors + 2 HSO + 1 BI)

- Communication media (see "Communication" below)

- External I/O modules (see "Accessories" below)

- AX007 External 6-channel 2-/3-wire RTD input module (pre-configured)

- AX008 External 8-channel thermocouple and mA input module (pre-configured)

- AX009 Raising frame (87 mm)

- AX010 Raising frame (40 mm)

- AX011 Combiflex frame

- AX012 Wall mounting bracket

We are ready to be your energy