AQ-F210 FEEDER PROTECTION DEVICE

The AQ-F210 feeder protection device offers a modular feeder protection and control solution, with non-directional overcurrent and earth fault protections with an automatic recloser. You can add up to four (4) I/O or communication cards into the device for more comprehensive monitoring and control applications. The AQ-F210 feeder protection device communicates using various protocols, including the IEC 61850 substation communication standard.

Highlights:

- Cable-end differential protection.

- Low-impedance restricted earth fault protection.

- Harmonics protection and control.

- A 5-shot scheme-controlled auto-recloser.

Technical Data

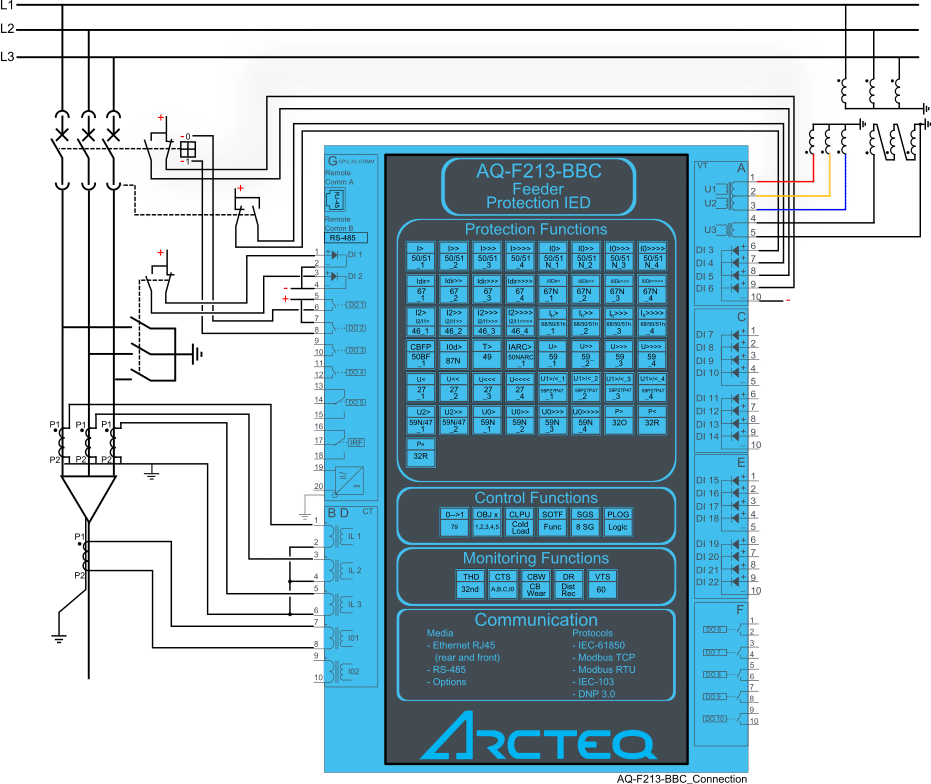

Application Drawing

Protection

Control

MEASURING AND MONITORING

COMMUNICATION

HARDWARE

ACCESSORIES

Technical Data

- Download PDF

- AQ 200 Series flyer v2.01 (English)

- AQ 200 Series product catalogue v1.03 (English)

- AQ-F213 Product flyer v1.02 (English)

- AQtivate PRO Flyer v1.00 (English)

- AQ-F210 Instruction manual v2.04 (English)

- AQ 200 series DNP3 device profile v4.00 (English)

- AQ 200 series DWG connection drawings (.zip file)

- AQ 200 series IEC 103 interoperability list v1.00 (English)

- AQtivate 200 Instruction manual v2.02 (English)

Application Drawing

Protection

- Non-directional overcurrent (I>; 50/51) - 4 stages (INST, DT or IDMT)

- Non-directional earth fault (I0>; 50N/51N) - 4 stages (INST, DT or IDMT)

- Negative sequence overcurrent/ Phase current reversal/ Current unbalance (I2>; 46/46R/46L) - 4 stages (INST, DT or IDMT)

- Harmonic overcurrent (Ih>; 50H/51H/68H) - 4 stages (INST, DT or IDMT)

- Circuit breaker failure protection (CBFP; 50BF/52BF)

- High-impedance or low-impedance restricted earth fault/ Cable end differential (I0d>; 87N)

- Resistance temperature detectors (RTD)

- Line thermal overload (TF>; 49F)

- Programmable stage (PGx>/<; 99)

- Arc protection (IArc>/I0Arc>; 50Arc/50NArc) (optional)

Control

- Number of objects to control and monitor: 5

- Number of indicators to monitor: 5

- Number of setting groups: 8

- Cold load pick-up

- Switch-on-to-fault

- Auto-recloser (0 → 1; 79)

MEASURING AND MONITORING

- Phase, sequence and residual currents (IL1, IL2, IL3, I01, I02)

- Current transformer supervision

- Circuit breaker wear monitoring

- Total harmonic distortion (current)

- Measurement recorder

- Measurement value recorder

- Event recorder (max. 15 000 permanent event records)

- Disturbance recorder (max. 100 records á 5 seconds at 3.2 kHz sampling)

COMMUNICATION

COMMUNICATION INPUTS

- RJ-45 100 Mbps Ethernet (front panel, fixed)

- RJ-45 100 Mbps Ethernet and RS-485 (rear panel, fixed)

- 2 x RJ-45 100 Mbps Ethernet with an IRIG-B input (optional)

- 2 x ST 100 Mbps Ethernet with an IRIG-B input (optional)

- 2 x LC 100 Mbps Ethernet (PRP/HSR) (optional)

- RS-232 serial fiber (PP/PG/GP/GG) (optional)

COMMUNICATION PROTOCOLS

- IEC 61850 (edition 1)

- IEC 60870-5-101/104

- IEC 60870-5-103

- Modbus/RTU and Modbus/TCP

- DNP3

- SPA

HARDWARE

- Current inputs: 5

- Digital inputs (fixed): 3

- Digital outputs (fixed): 5

- Number of empty slots: 4

- Digital inputs: +8/16/24/32 (optional)

- Digital outputs: +5/10 (optional)

- Milliampere I/O module (4 mA outputs + 1 mA input)

- Arc protection module (4 sensors + 2 HSO + 1 BI)

- Communication media (see "Communication" below)

- External I/O modules (see "Accessories" below)

ACCESSORIES

- AX007 External 6-channel 2-/3-wire RTD input module (pre-configured)

- AX008 External 8-channel thermocouple and mA input module (pre-configured)

- AX009 Raising frame (87 mm)

- AX010 Raising frame (40 mm)

- AX011 Combiflex frame

- AX012 Wall mounting bracket

We are ready to be your energy